Company News & Updates

28 Mar 2024

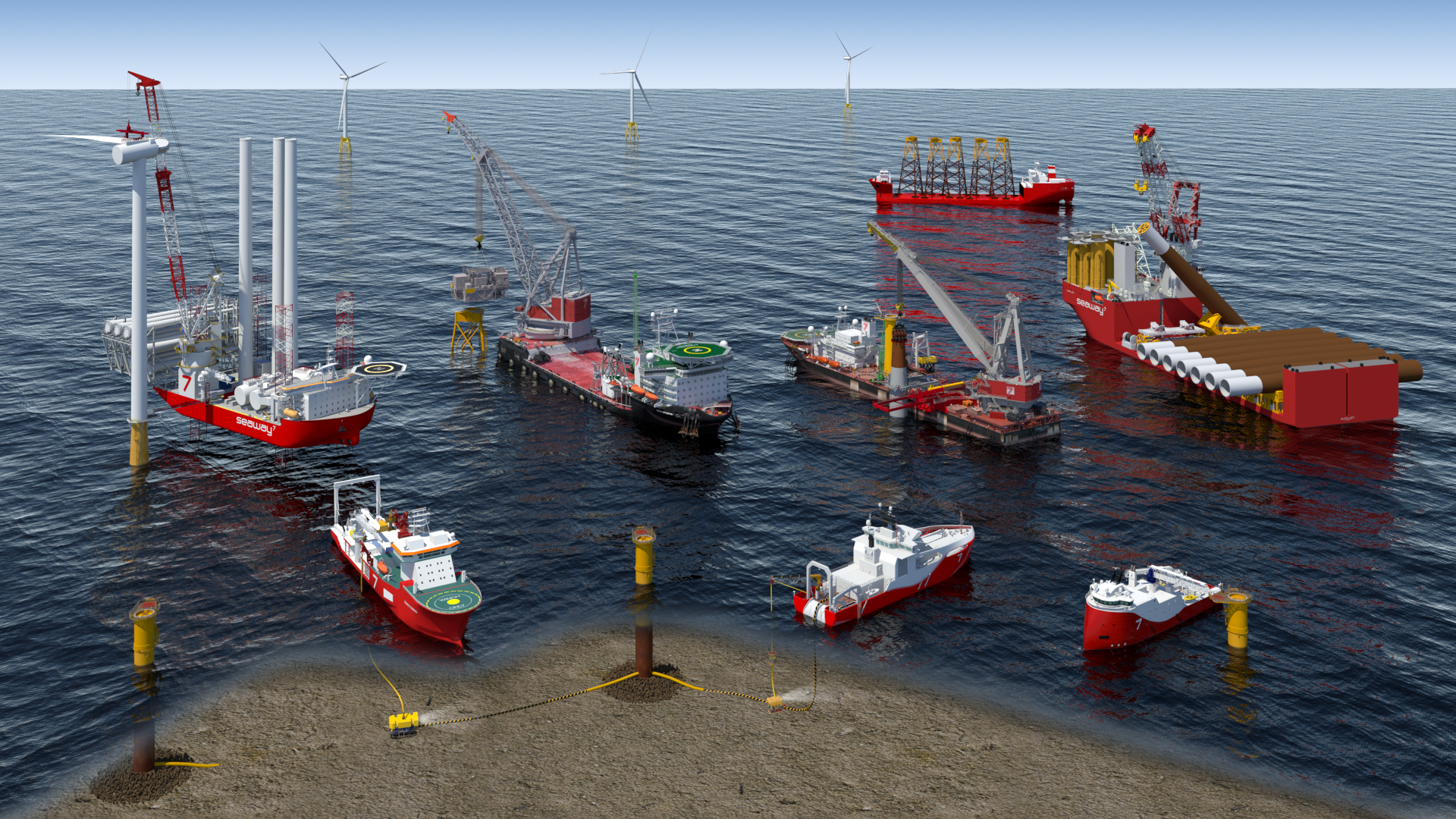

Seaway7 awarded substation contract offshore Poland

Seaway7 has today announced the award of a sizable contract by PGE Polska Grupa Energetyczna and Ørsted for the transport and installation of the substations for the Baltica 2 wind farm, offshore Poland.

Seaway7’s scope includes the transport and installation of four substations. Offshore activity is scheduled to take place in 2026 utilising both our heavy lift and heavy transportation vessels.

Baltica 2 is a 50:50 joint venture between PGE Polska Grupa Energetyczna and Ørsted. The wind farm, with a capacity of around 1.5 GW, will be located in the Polish sector of the Baltic Sea ar

7 Feb 2024

Seaway7 and Dong Fang Offshore collaborate on Offshore Wind in Taiwan

From left: Stuart Fitzgerald, CEO, Seaway7 and Polin Chen, COO, Dong Fang Offshore.

Seaway7 and Dong Fang Offshore (DFO) are pleased to announce that they have signed a Memorandum of Understanding outlining their intention to collaborate in an exclusive manner and further strengthen their offering to the offshore wind market in Taiwan. The collaboration will focus on developing a robust localised cable installation offering for the Taiwanese offshore wind projects to our clients.

Seaway7 has been operating in Taiwan since 2017, and today employs more than 100 people between their office in Tai

6 Dec 2023

Seaway7 Receives Fleming Award for Seagreen

It is with great pride that we share that Seaway7 has been awarded the prestigious Fleming Award for the Seagreen Offshore Wind Farm project. The Fleming Award is awarded annually by the British Geotechnical Association to recognise excellence in project teams in the practical application of geotechnics in a project.

Seaway7 was the Engineering, Procurement, Construction and Installation (EPCI) contractor for foundations and cables on the Seagreen Offshore Wind Farm, a joint venture between SSE Renewables and TotalEnergies.

Dr Nawras Hamdan, Specialist Geotechnical Engineer, and Mark MacBeath,

24 Oct 2023

Seaway7 awarded contract offshore Poland

Seaway7, part of the Subsea7 Group, today confirmed the award of a substantial1 contract by Equinor and Polenergia for the inter-array cables of the MFW Bałtyk II and MFW Bałtyk III bottom-fixed offshore wind projects, in the Polish part of the Baltic Sea.

Seaway7’s scope of work covers the engineering, procurement, construction and installation (EPCI) of 100 66kV inter-array cables, measuring approximately 200 kilometres in length. The two projects will be delivered in continuous campaigns with offshore works expected to commence in 2026.

MFW Bałtyk II and MFW Bałtyk III, a 50:5

12 Sep 2023

Seaway7 Sponsors Offshore Site Investigation and Geotechnics Conference (OSIG)

Seaway7 is pleased to be a main sponsor at the highly anticipated 9th International Offshore Site Investigation and Geotechnics Conference (OSIG) taking place in London this week.

The sold-out event, organised by the Society for Underwater Technology, is the longest standing international conference series of this type and has significantly grown this year. It brings together the offshore Geotechnical, Geophysical and Geoscientific industry, and academic communities to share the latest research, knowledge and experience.

The conference includes 10 Keynote Addresses, 22 conference sessions and

29 Aug 2023

Seaway7 Team Up with OffshoreWind4Kids

Seaway7 teamed up with OffshoreWind4Kids this year to encourage education in science, technology, engineering and maths, whilst showcasing the possibilities of careers in offshore wind.

Last weekend Seaway7 hosted a third offshore wind demo day, this time in Oslo, giving children and their families the opportunity to build and install their own wind turbine. This followed sessions held earlier this year in the UK and the Netherlands with around 100 children and their families benefiting in total.

Organisation Development Coordinator Paige Quirie, who has driven the partnership with OffshoreWin

30 Jun 2023

Seaway7 awarded East Anglia 3 contract

Seaway7, part of the Subsea7 Group, today confirmed the award of a very large1 contract by ScottishPower Renewables for the transport and installation of the foundations and inner-array cables for the East Anglia THREE offshore farm. The award comes a year after the Preferred Bidder Agreement was announced

East Anglia THREE – located in the Southern North Sea, 69 kilometres off the Suffolk coast – will be the world’s second largest windfarm when it comes into operation in 2026. Its 95 14.7MW turbines will have a combined capacity of 1,400MW, generating enough green electricity to pow

17 Apr 2023

Final jacket foundation installed on Seagreen

Seaway7 has installed the final wind turbine foundation on Seagreen Offshore Wind Farm, off the coast of Angus, Scotland, concluding the 18-month installation campaign. The 114th jacket foundation was successfully installed late afternoon on Thursday 13th April by the Saipem 7000 crane vessel, which was used to lift each of the 2,000-tonne foundations into place.

As the main contractor, Seaway7 has managed the engineering, procurement, construction, and installation of the wind turbine generator foundations and is installing approximately 300km of associated inner-array cables.

This major mile

9 Mar 2023

Seagreen Hazard Observation Card Award

Seaway7, in partnership with and Seagreen Wind Energy Limited and Global Energy Group, have been running Hazard Observation Card Award initiative since last summer aimed at promoting a ‘safety first’ and ‘open culture’ among employees and contractors involved with the Seagreen project at the Port of Nigg.

The latest winner of the Hazard Observation Card Award initiative — Les Simpson, QC Inspector for Seaway7— has thoughtfully selected Macmillan Cancer Support as the recipient of the monthly charity donation.

Macmillan is a UK organization, comprising millions of dedicated support

23 Feb 2023

Seaway7 and Saipem Announce Fixed Offshore Wind Commercial Collaboration Agreement

Seaway7 today announced that it has entered into a commercial collaboration agreement with Saipem to jointly identify, bid and execute fixed offshore wind projects.

Seaway7 and Saipem will pursue selected projects where the combined utilisation of the companies’ complementary world-class assets, technologies, products and competencies will generate significant synergies and improve project economics.

Seaway7 and Saipem will deploy key enabling assets and capabilities to cover activities such as front-end engineering design (FEED), procurement, construction, transportation and installation of

Company News

21 Feb 2023

Seaway7 Signs Transport and Installation Cables Contract for Hai Long Offshore Wind Farm

Seaway7 is pleased to announce that it has signed a contract with Hai Long Offshore Wind Power for the installation of inner-array grid and export cables on the Hai Long Offshore Wind Project in Taiwan. This contract award completes the key procurement for the project which is now steadily moving into construction phase.

The signing ceremony took place today at the Hai Long offices in Taipei. It follows the contractual signing which was announced to the market last week on 14th February 2023.

The scope of work includes the transport and installation of inner-array cables, the respective ca

Company News

14 Feb 2023

Seaway7 Awarded Transport and Installation Cables Contract

Seaway 7 ASA (Euronext Growth: SEAW7) is pleased to announce that it has been awarded a large(1) contract for the transport and installation of inner-array grid and export cables on an undisclosed offshore wind farm project.

The scope includes the transport and installation of inner-array and export power cables and respective cable protection systems. Operations on the project will commence in 2023 and continue through 2024 and 2025.

The project remains subject to client final investment decision (FID).

(1) “Large” contracts are between $300m and $500m.

TOMBROK

TOMBROK