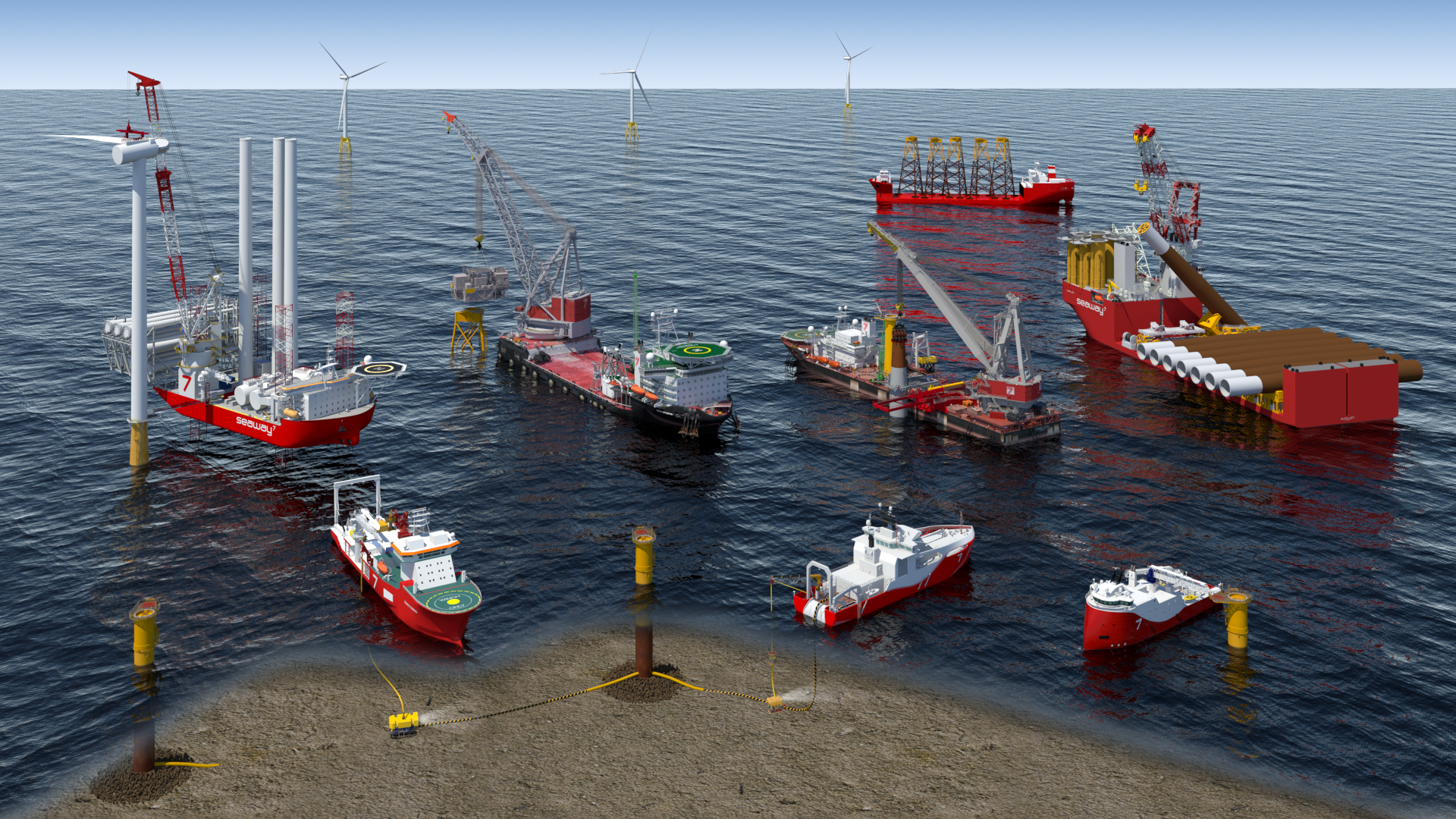

For installation, we are using an impact hammer and/or vibratory hammer depending environmental and soil conditions. To minimise the environmental impact, Seaway7 will provide pile driving noise mitigation measures based on the latest available technology.

Following a multi-year innovation program, we have developed and successfully tested a method whereby monopiles can be installed on dynamic positioning. To date, installing monopile foundations on anchors rather than using dynamic positioning has been the norm. This specialised solution allows us not only to reduce our installation cycle times but the overall project duration and the associated cost. Any limitations with regards to impacting the seabed or local infrastructure have all but been removed.

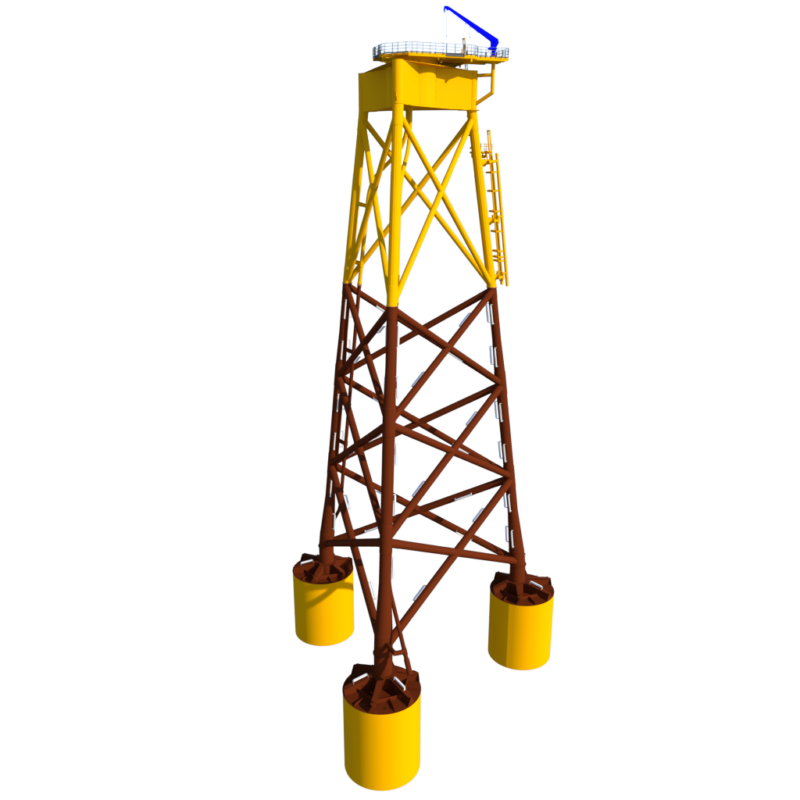

TOMBROK

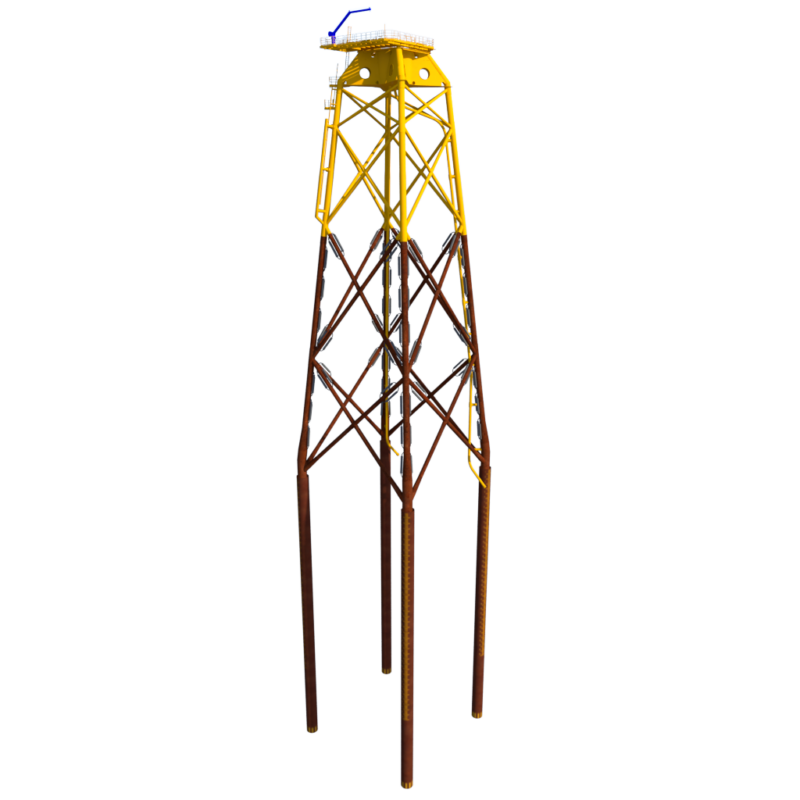

TOMBROK